Pen Ink Experiments

As I mentioned in my last post, I am currently waiting to assess the results of my experiment in making dipping ink. As I am still becoming familiar with the terminology, I will specify that I am using the term “pen ink” to describe a pigmented liquid with a viscosity much closer to water than to screen printing ink (which is my frame of reference). Naturally, I am testing the inks with what I had once referred to as a calligraphy pen- a dip, or nib pen.

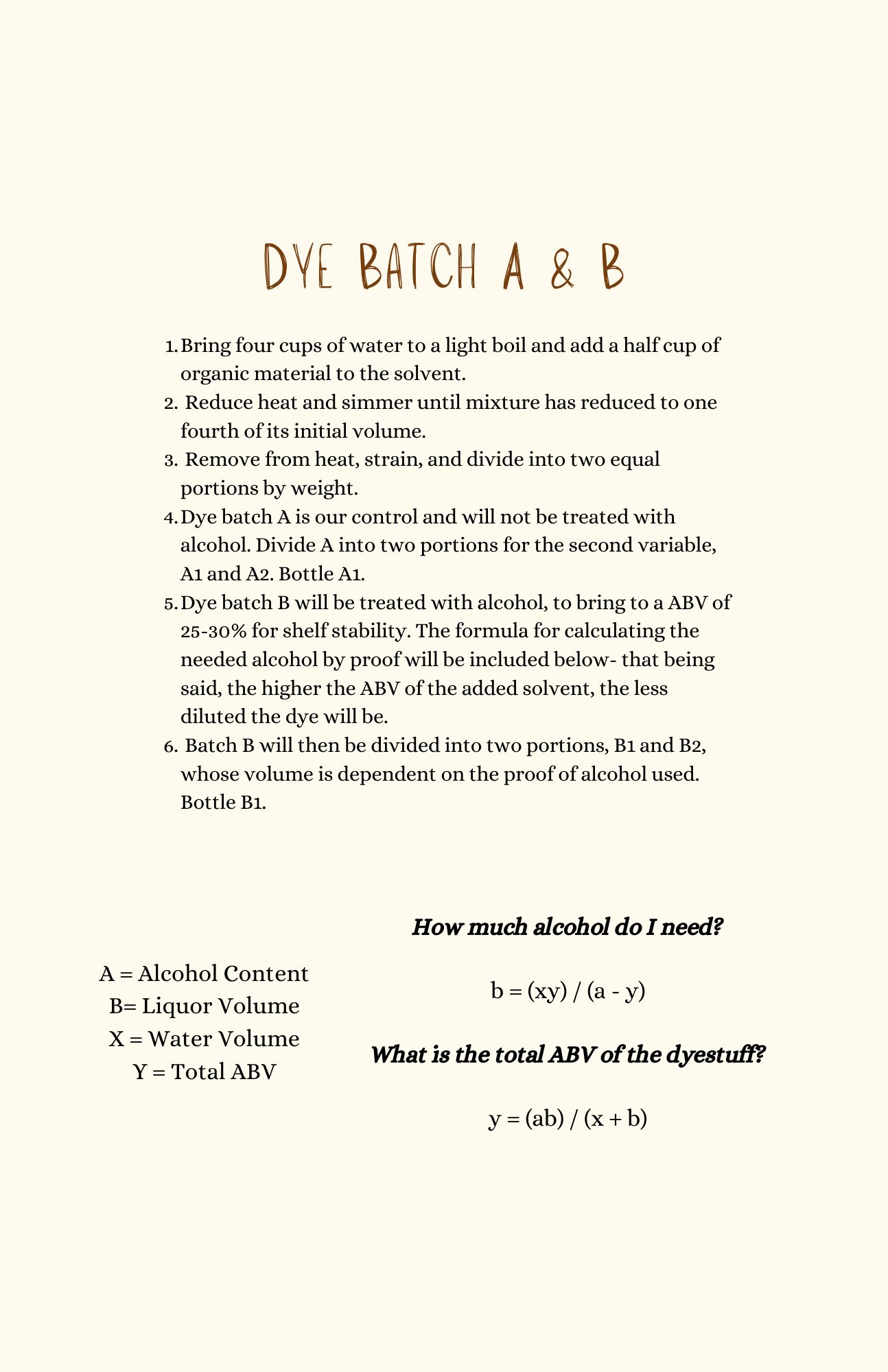

Creating the Inks

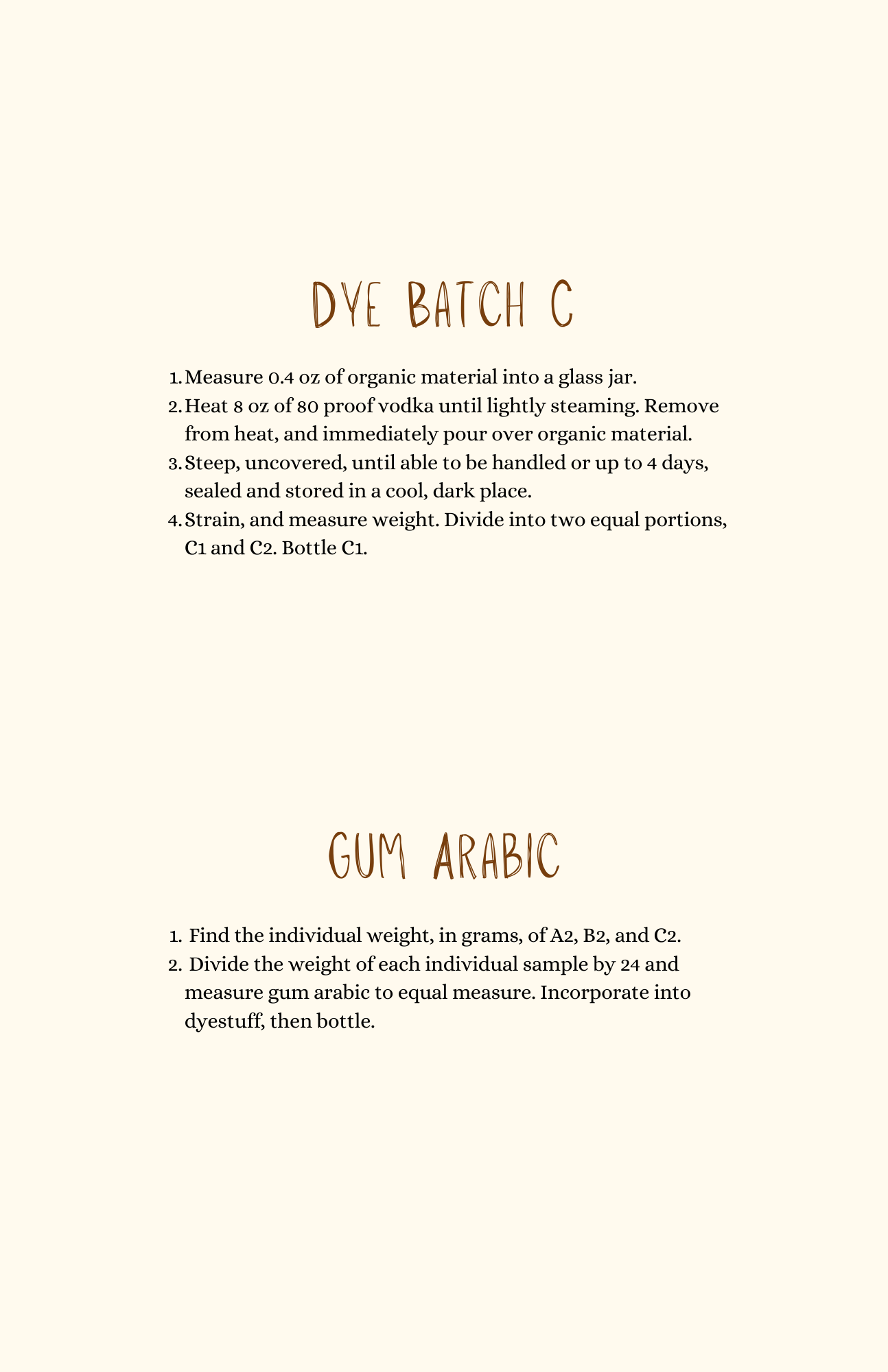

I made batch C first, as I had intended to allow the material to steep for at least several days. I used a cheap 80 proof vodka as my alcohol. To prepare the flowers, I plucked the calyx from the dried flowers and unfurled the petals to increase the surface area. Removal of the calyx is not necessary for dyeing. I only do so as I am saving this material for future investigations into its dye potential and impact on color outcome. I suspect it has some effect on PH, but that’s beside the point.

Rather than the two nights I had planned to steep the mixture, I ended up only waiting six hours before straining. When it came time to seal the jar, I realized that my lid was not airtight- the dye readily leaked out of the jar. This was poor foresight on my part, though by no means devastating. After only a few hours, the dye was already highly pigmented, so I decided to continue with the experiment as normal.

Next were batches A and B. For this, I used four cups of well water. Due to the minerals present, we don’t ingest this water, which was fine for the purposes of this experiment. However, I realize in retrospect that this may have introduced unknown materials into the dye, materials which may have impacted tested variables. In the future, I’ll be sure to use purified, or at least filtered water.

Again, I had a slight mishap. After several hours of brewing, at which point the liquid had reduced by about a fourth, I had to pause the heating to attend to some unexpected errands. While I’d rather not have left the mixture to cool, I did not notice any changes resulting from this. Two to three hours later, I brought the dye bath back up to a simmer, where it continued evaporating for another three hours. Having reduced to 25% of its original height, I divided the drained liquid into two bowls, weighing them to determine equally sized portions, labeled A and B.

I’ve misplaced my records as to the volume of alcohol I incorporated, and should I find them, will make the proper edits to document them. In any case, I estimated that batch B was between 20 to 25% alcohol by volume. This was slightly below what I had planned, as 25% is generally accepted for shelf stability, but I was concerned that more spirits would dilute the pigment too much.

Batches A, B, and C were then each divided into two equal portions by weight. The portions that would not be treated in the next stage, A1, B1, and C1, were then bottled in amber glass and refrigerated.

In the final steps of the process, gum arabic was incorporated into A2, B2, and C2. Initially measuring the dry powder out to roughly one twentieth of the liquids weight in grams, specific measurements were quickly abandoned for impracticality. Instead, I elected to mix in the powder until some level of thickening occurred. This was much more subtle than I had anticipated, particularly for the quantities of gum arabic that were used. Some of this is surely the result of poor mixing, as I had a great deal of trouble incorporating the materials. A better approach would have been to treat the gum arabic as cornstarch, mixing it very well with a small amount of liquid before introducing it to the whole.

As with the others, these batches were then bottled and refrigerated.

Initial Impressions

Batches A and B were highly similar in overall color and viscosity, with C standing out with a much more purple tone and high degree of spread. This was entirely unexpected, and rather disappointing. A far more pleasant surprise was the degree of control offered to me by the pen.

Between the batches labeled 1 and 2, some improvements in viscosity were noted. These improvements, however, were rather subtle, offering no real progress in usability that were not accomplished in the shift from brush to pen.

Interestingly, the use of the pen produced a slightly inconsistent navy tone to the ink, whether or not it was treated with gum arabic. As this tone suggests an increased acidity, my current theory is attributes this change to a reaction to the iron pen nib.

It has been two weeks since this initial experiment, and I have a fair idea of the ink’s colorfastness. Now all that’s left is to assess its shelf stability. In all likelihood, I’ll let my impatience get the better of me, and will have some idea of its stability by the end of the week. In that update, I will, of course, include images to document the results.